Blog

Yuhua Fused Cast

The outstanding performance of electrofused zirconia-corundum bricks in the glass industry

Time:

Aug 07,2025

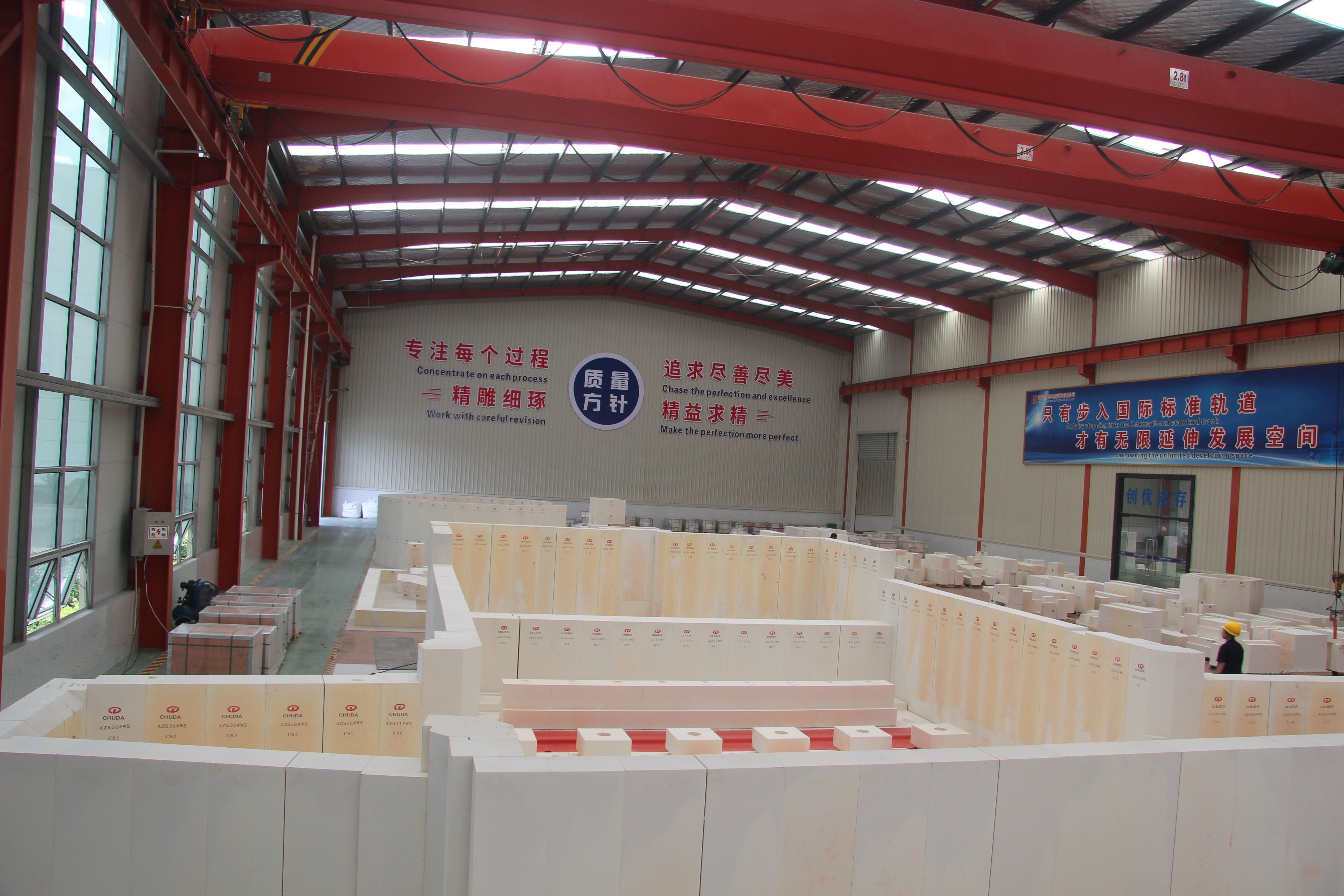

In the glass industry, electrofused zirconia corundum bricks are indispensable key materials due to their superior performance and characteristics.

Electrofused zirconia corundum bricks play a significant role in various key areas of glass furnaces, such as the bottom, walls, and regenerator checker bricks. In these high-temperature and glass melt erosion environments, electrofused zirconia corundum bricks, with their high refractoriness and strong erosion resistance, ensure stable furnace operation and extended service life.

In areas of glass furnaces with particularly high requirements for erosion resistance, such as all-electric melting furnaces, flow holes, kiln walls, bubbling areas, and charging port corners, electrofused zirconia corundum bricks also perform exceptionally well. They not only withstand high temperatures and erosion but also resist the scouring and wear of the glass melt, ensuring the stable operation of these parts and improving the quality and efficiency of glass production.

The low pollution characteristic of electrofused zirconia corundum bricks is another reason for their popularity in the glass industry. In glass production, the choice of refractory materials significantly impacts glass quality. The low pollution characteristic of electrofused zirconia corundum bricks means that they cause minimal contamination of the glass melt during use, helping maintain glass quality and purity.

With their excellent erosion resistance, wear resistance, scouring resistance, and low pollution characteristics, electrofused zirconia corundum bricks play an irreplaceable role in the glass industry. As the glass industry continues to develop, the application range of electrofused zirconia corundum bricks will further expand, providing more stable, efficient, and environmentally friendly solutions for glass production.

Recommended content

Share to

CONTACT US

WhatsApp:

E-mail:

Tel :

Address:

The Industry Park, XinMi City, Henan Province

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.