Category

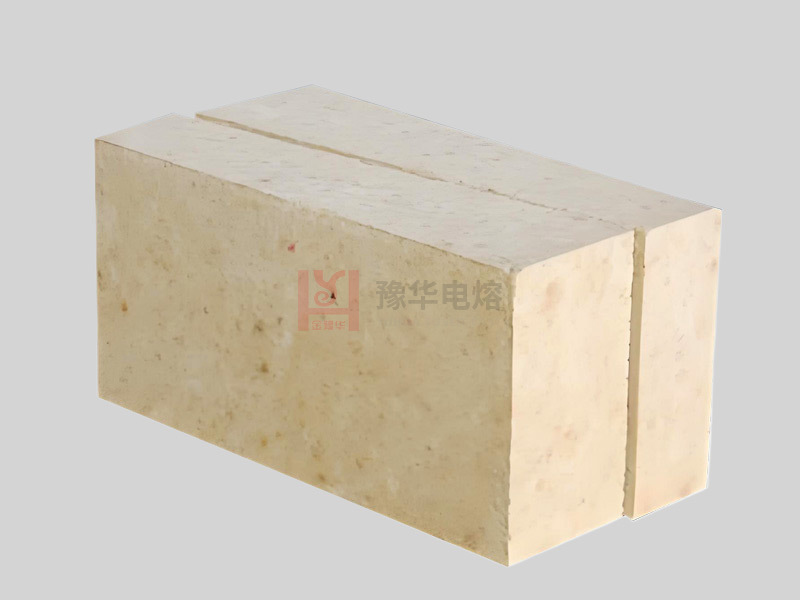

Low porosity clay brick is used as the main raw material, with the addition of aluminum-silicon materials such as pyroxene, silica wire stone, rhodochrosite, etc., and the clay products with low porosity are pressed and fired. It is characterized by high compressive strength, erosion resistance, high load softening onset temperature and good thermal shock stability at low and medium temperatures.

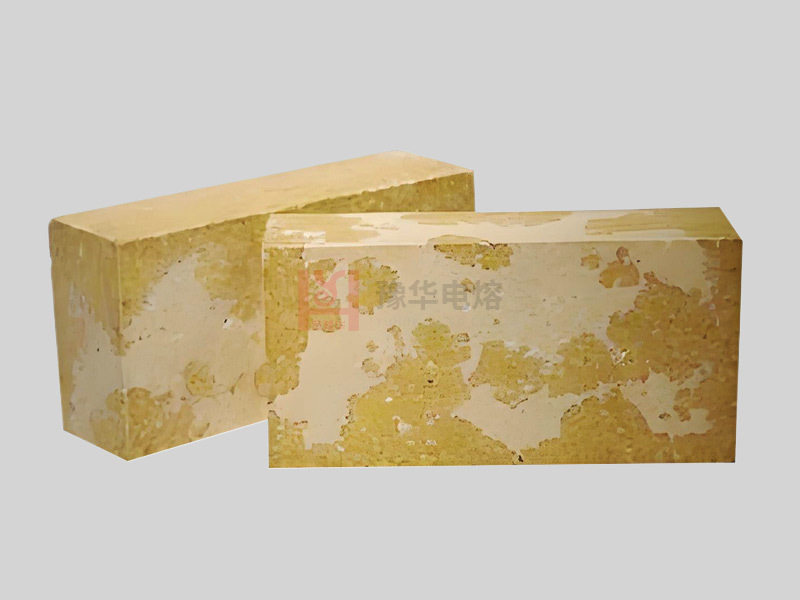

View DetailsFused cast recombined magnesium-chromium bricks are also known as fused magnesium-chromium bricks. High-temperature performance between fused magnesium-chromium bricks and sintered magnesium-chromium bricks, its load softening temperature up to 1700 ℃. Generally the first light burning magnesium oxide and chrome ore as raw materials, with an electric arc furnace will be made of fused magnesium-chromium sand, and then by crushing, grinding, batching, molding, firing and made. The application field of this kind of bricks is similar to that of ordinary magnesium-chromium bricks.

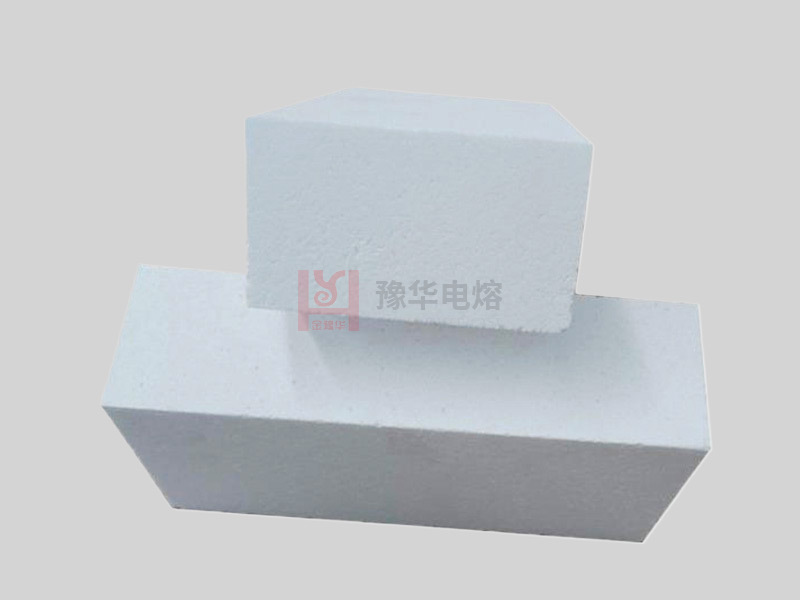

View DetailsHigh-alumina brick is a refractory material, the main component of this refractory brick is Al2O3. In China, according to the high-alumina bricks in the Al2O3 content is usually divided into three levels: first-class high-alumina bricks Al2O3 content of > 75%; second-class high-alumina bricks Al2O3 content of 60 ~ 75%; third-class high-alumina bricks Al2O3 content of 48 ~ 60%.

View DetailsThe raw materials for the production of silica bricks mainly include silica, rhodochrosite, zircon, mullite, alumina powder, and binding clay. Through the high temperature tunnel kiln at 1450~1500 ° C temperature insulation 10~12 hours firing, natural cooling 48~52 hours after the finished brick billet out of the kiln, get high temperature silica brick.

View DetailsSilicon bricks maintain good structural strength and stability at high temperatures, have a long service life, are highly resistant to erosion by acidic furnace gases and molten glass, and have good thermal conductivity, which reduces heat loss and improves the thermal efficiency of the furnace. Silica bricks are widely used in the key parts of glass kilns: the roof swan, the flue swan,

View DetailsAnti-spalling high alumina bricks are made of high alumina bauxite as the main raw material, adding zirconia-containing materials or other raw materials, according to a certain ratio by the brick press after molding, drying, high-temperature calcination and become. Anti-scaling high alumina bricks are divided into two categories according to chemical composition, one is containing zirconium dioxide (ZrO2), model GKBL-70; the other is not containing zirconium dioxide (ZrO2) model KBL-70.

View DetailsZero expansion silica brick main ingredients: 90% fused silica, ultrafine silica powder 8%, carboxymethyl cellulose 0.1%, silica sol 0.5%. It has good erosion resistance and creep resistance to the burning atmosphere in the glass kiln, does not crack, does not deform in the high temperature above 1500 ℃, no spalling phenomenon in long-term use, the masonry brick body is more dense, will not affect the quality of glass liquid, suitable for glass kiln swan hot patch, heat insulation replacement, and so on.

View DetailsMagnesium brick is a kind of high-grade refractory bricks, mainly with fused magnesium sand or sintered magnesium sand as the main raw material, according to the use of the environment and the use of adding binding agent, binder, in accordance with the proportion of proportion, after mixing, molding, drying, and then into the kiln firing or electrofusion.

View DetailsLightweight silica bricks have excellent refractory properties, load softening temperature close to dense silica bricks up to 1620 ℃, only a small residual expansion, and its thermal stability than dense silica bricks good. Therefore, lightweight silica bricks can be used for a long time under high temperature conditions (1500~1550℃) without contacting with slag, which is suitable for the lining of large-scale blast furnace supporting hot air furnace, glass kiln heat insulation layer, etc.

View DetailsAlumina hollow ball brick refractoriness up to 1750 degrees or more, good thermal stability, re-firing line change rate is small, durable. Strong thermal insulation characteristics, low thermal conductivity. Alumina hollow ball brick can be used in high temperature energy-saving inverted flame kiln, shuttle kiln, molybdenum wire furnace, tungsten rod furnace, induction furnace, nitriding furnace and so on.

View DetailsThe main raw materials for clay cast large bricks are formulated using bauxite and pyroxene as aggregates, as well as silicon oxide powder, alumina micropowder, calcium aluminate cement and water reducing agents.

View DetailsThe corundum thermal storage ball has significant characteristics such as low iron content, high density, good crystallization, high temperature resistance, corrosion resistance, high strength, good thermal shock stability, large heat storage and release capacity, and good thermal conductivity.

View Details