Category

Fused cast mullite has a low content of oxides and a relatively high content of elements such as potassium and calcium aluminum silicate.Fused cast mullite is mainly used in high temperature, high pressure and other severe conditions, such as molten metal, high-temperature furnace wall, glass kiln forehearth, pool wall and other external insulation, auxiliary bottom, etc.

View DetailsIt is zirconia brick, which plays an important role in several industries due to its excellent physical and chemical properties. First, zirconia bricks have excellent corrosion resistance and can effectively resist acid and alkali erosion at high temperatures and in acidic and alkaline environments, thus extending the service life of the kiln. Secondly, the excellent wear resistance of zirconia bricks makes them popular in mining, metallurgy and other industries, which can reduce the degree of wear and tear of the equipment and improve the efficiency and life of the equipment. In addition, zirconia bricks also have excellent thermal conductivity, which can effectively conduct heat and improve the heating or cooling efficiency of the equipment, which is particularly important in metallurgy, electronics and other industries.

View DetailsThe zircon brick maintains stable performance at high temperature, has a high load softening temperature.

View DetailsChromium corundum bricks have excellent refractory properties, its refractoriness and load softening temperature are greater than 1700 ℃, better than high purity corundum products. This is because Al2O3 and Cr2O3 can form a continuous solid solution without low eutectic generation, which improves the refractory performance of the material.

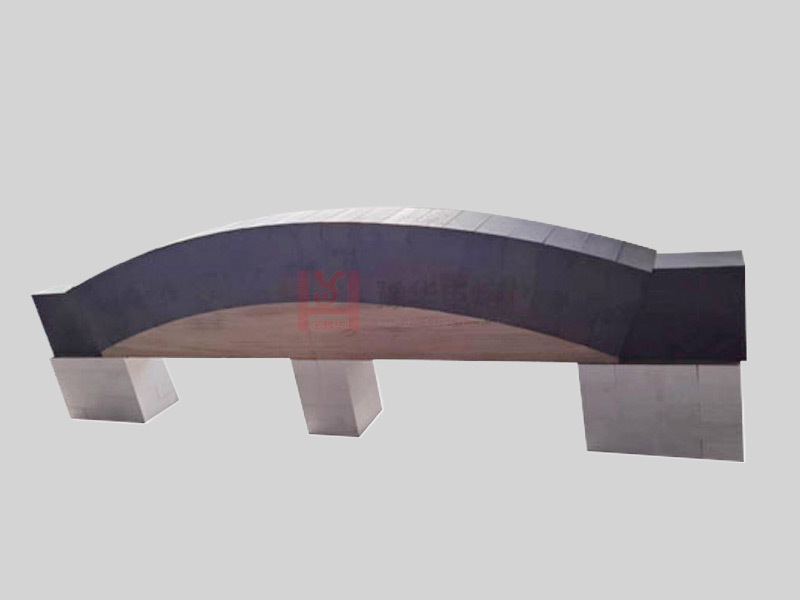

View DetailsChromium zirconium mullite (three resistance brick) is specially designed for industrial kilns petrochemical and glass kilns tongue swan, lattice body with refractory bricks, tongue swan complex and its harsh conditions of use, must require refractory bricks with resistance to alkali, sulfur, fluorine, alum and other substances such as high-temperature corrosion, but also to withstand the thermal stress caused by temperature fluctuations in the heat storage room fire exchange. Chromium-zirconium mullite brick main crystal phase is mullite and high-temperature slag-resistant polycrystalline phase, using high-pressure molding, high-temperature firing products with high-temperature resistance to thermal shock, resistance to cracking, resistance to slag erosion and other excellent high-temperature performance, can completely solve the tongue-swan and coal dust, coal tar combustion kiln furnace heat storage room brick problem.

View DetailsMagnesia-zirconia bricks are made of high-purity electrofused magnesia and synthetic magnesia-zirconia sand, which are molded under high pressure and fired at high temperature.

View DetailsSintered AZS zirconium corundum bricks are made of high-quality zirconium (ZrO2) as the main raw material, after scientific and reasonable grading, and additives with excellent performance, high pressure molding, high-temperature sintering made of refractory products, which are characterized by high strength, high-temperature resistance, resistance to erosion, and good chemical stability.

View DetailsMullite bricks are high alumina refractories with mullite as the main crystalline phase. The general alumina content is between 70% and 80%. Mineral composition in addition to mullite, which contains low alumina also contains a small amount of glass phase and quartz; high alumina also contains a small amount of corundum.

View DetailsZircon mullite brick has good chemical stability, with characteristics such as high temperature resistance, acid and alkali corrosion resistance, and thermal shock resistance. It is widely used in ultra-high temperature kilns and steel continuous casting in industries such as military, scientific research, high melting point metal smelting, laser crystals, quartz glass, and electronics.

View DetailsCorundum bricks refer to refractory brick products with an Al2O3 content greater than 90%, primarily composed of corundum as the main crystalline phase. They have high compressive strength at room temperature (up to 140 MPa) and a high load softening temperature (greater than 1700°C).

View Details