Category

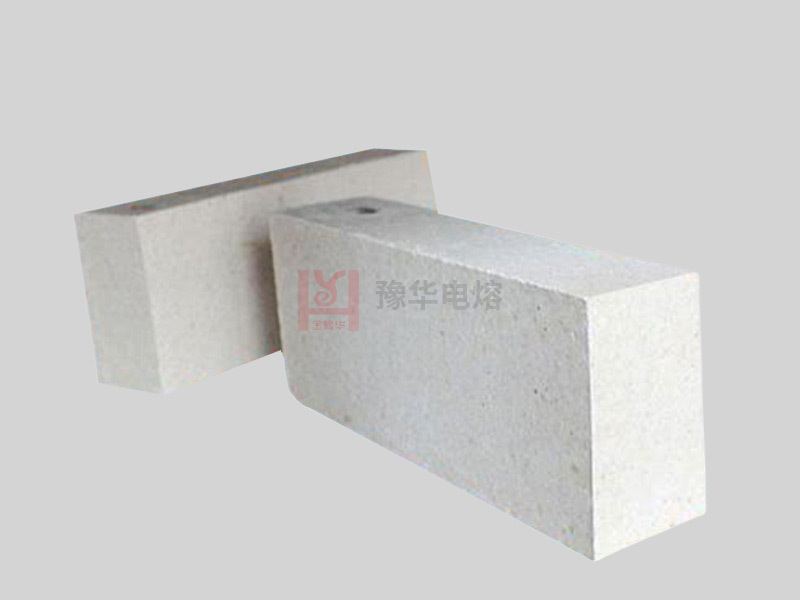

Lightweight silica brick

Classification:

Product Introduction

Product Details

Production method:

Lightweight silica brick has excellent fire resistance, the load softening temperature is close to the dense silica brick up to 1620 degrees C, only a small residual expansion, and its thermal stability is better than dense silica brick. Therefore, the light silica brick can be used for a long time under the condition of high temperature (1500~1550 ℃) without contact with slag, and is suitable for the lining of large blast furnace and the insulation layer of glass furnace.

Product Details: Siliceous heat-insulating refractory bricks are heat-insulating siliceous refractory products with SiO2 content above 90% and volume density less than 1.2g/cm³. The mineral composition of silicon thermal insulation refractory brick is: phosphorus quartz 78% ~ 86%, cristobalite 13% ~ 15%, quartz 4% ~ 7%. Crystalline quartzite or silica sand is generally used as raw material, and flammable substances such as coke, anthracite, sawdust, carbonized rice husk or gas foaming method are added to the ingredients to form a porous structure. The fire resistance and load softening temperature are not much different from ordinary silica bricks with the same composition. However, due to many pores, the compressive strength, slag resistance and corrosion resistance are not as good as those of ordinary silica bricks, while the thermal shock resistance is improved.

Product characteristics: light silica brick has excellent fire resistance, load softening temperature close to dense silica brick up to 1620 ℃, there is a small residual expansion, and its thermal stability is better than dense silica brick. Therefore, the lightweight silica brick can be used for a long time under the condition of high temperature (1500-1550 ℃) without contact with the slag, and is suitable for the lining of large blast furnace and the gas insulation layer of glass furnace.

Product use: Lightweight silica bricks are suitable for coke ovens, hot air stoves, glass furnaces, carbon kilns, etc. General lightweight silica bricks are divided into: level 1 and level 2: level 1 lightweight silica bricks can be used for rolling steel heating furnace top and silicate industrial kiln top and other parts, can be directly in contact with the flame; level 2 lightweight silica bricks are used for general industrial kiln insulation layer.

Physical and chemical indicators:

Physical And Chemical Index | |||

Physical And Chemical Indexes Of Light Silica Brick | |||

Performance Index | QG-1.0 | QG-1.1 | QG-1.2 |

Bulk Density | 1 | 1.1 | 1.2 |

Normal Temperature Compressive Strength/Mpa | 3 | 4 | 5 |

Test Temperature With Re-burning Line Change ≤ 2% (℃) | 1450 | 1500 | 1550 |

Thermal Conductivity 350 ℃ ± 10 ℃(W/m.k)≤ | 0.5 | 0.6 | 0.7 |

Starting Temperature Of softening Under Load of 0.1MPa/℃ | 1400 | 1420 | 1520 |

Chemical Composition% SiO2 | 91 | 91 | 91 |

Keywords:

Lightweight silica brick

Silica brick 96A

Kiln Display

Feedback

Leave an online message and get free product quotes