How to distinguish the quality of electric melting bricks

Time:

Feb 21,2025

Identifying the quality of electric melting bricks from glass kilns can be approached from multiple aspects such as appearance, physical and chemical properties, production process, and manufacturers. Below is a detailed introduction for you:

1. Appearance Inspection

11. Size Specification: Use professional measuring tools, such as calipers and tape measures, to strictly measure the key dimensions of electric melting bricks, including length, width, height, and thickness, according to relevant standards or contract requirements. For example, the standard specifies that the length of a certain model of electric melting brick is300mm, with an allowable error of ±1mm. If the measured value exceeds this range, it may affect the masonry quality and usage effect.

22. Surface Defects: Carefully observe whether there are cracks, holes, sand holes, missing corners, or chipping on the surface of the electric melting bricks. Tiny cracks may gradually expand during use, reducing the strength and lifespan of the bricks; holes and sand holes can affect the density of the bricks, weakening their corrosion resistance and wear resistance.

33. Color Uniformity: High-quality electric melting bricks usually have a more uniform color due to oxygen blowing. If there are significant color differences on the surface, such as darkening or bluish hues, it may indicate problems in the raw material mixing or melting process, leading to uneven composition and affecting the performance of the bricks.

2. Physical and Chemical Property Testing

2. Physical and Chemical Property Testing

11. Density Testing: Generally, electric melting bricks with larger and more uniform density have a denser internal structure, better strength, and corrosion resistance. The density of electric melting bricks can be measured using the drainage method or gas porosity density meter, and compared with the standard density range for that type of electric melting brick.

22. Hardness Testing: Use hardness testing equipment, such as a Mohs hardness tester, to measure the hardness of electric melting bricks. Bricks with higher hardness have better wear resistance and can be used longer in environments with material scouring and friction.

33. Corrosion Resistance Assessment: Determine the chemical composition of electric melting bricks through chemical analysis methods to understand their tolerance to specific chemicals. Corrosion resistance tests can also be conducted by soaking electric melting brick samples in specific corrosive media for a certain period, observing changes in quality and surface corrosion, and assessing their corrosion resistance.

44. Thermal Performance Testing: Test the thermal expansion coefficient, thermal conductivity, and other thermal performance indicators of electric melting bricks. The thermal expansion coefficient should be within an appropriate range; too large or too small may affect their performance in high-temperature environments. The thermal conductivity requirements vary according to specific usage scenarios and must meet corresponding standards.

3. Production Process and Manufacturer Reputation Investigation

3. Production Process and Manufacturer Reputation Investigation

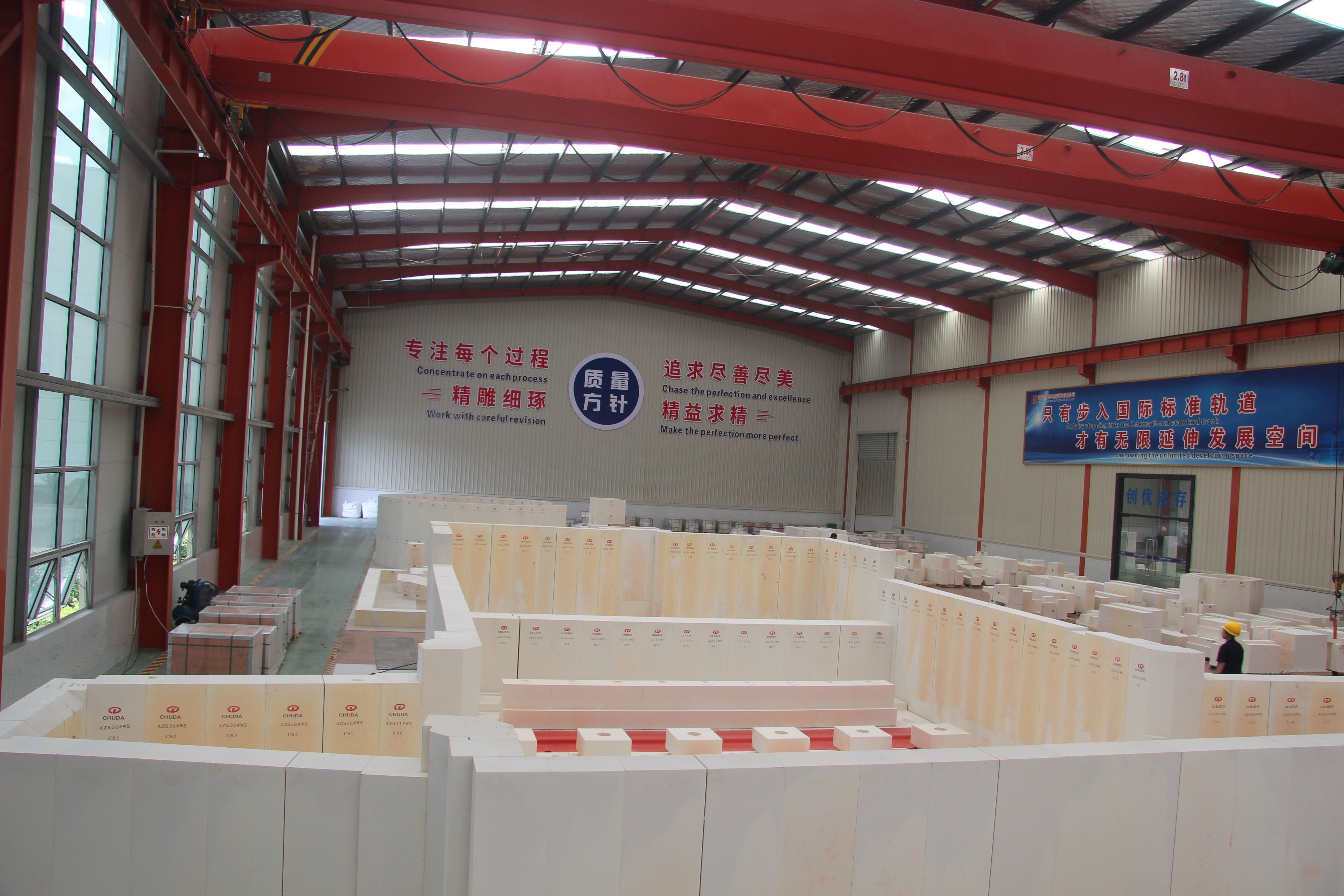

11. Production Process: Advanced production processes are key to ensuring the quality of electric melting bricks. Understand the manufacturer's production processes, such as raw material selection and pretreatment, melting equipment and process parameters, forming methods, and heat treatment processes. Electric melting bricks produced using advanced equipment and reasonable processes have more guaranteed quality.

22. Manufacturer Reputation: Choose electric melting bricks produced by manufacturers with good reputation and word-of-mouth. You can understand the manufacturer's production capacity, quality control system, and after-sale service level by checking the manufacturer's qualification certificates, three-body certification, customer evaluations, and achievements. Manufacturers with good reputation usually have stricter control over product quality and can provide more reliable products and technical service support.

4. Internal Structure Inspection

4. Internal Structure Inspection

11. Non-destructive Testing: Use non-destructive testing methods such as ultrasonic testing,Xray testing, etc., to check whether there are cracks, looseness, and other defects inside the electric melting bricks. These internal defects may not be detectable from the outside but can severely affect the performance and lifespan of the bricks.

22. Microscopic Structure Analysis: Observe the microscopic structure of electric melting bricks using equipment such as microscopes to understand their grain size, distribution, and phase composition. A uniform and fine grain structure usually indicates better performance.

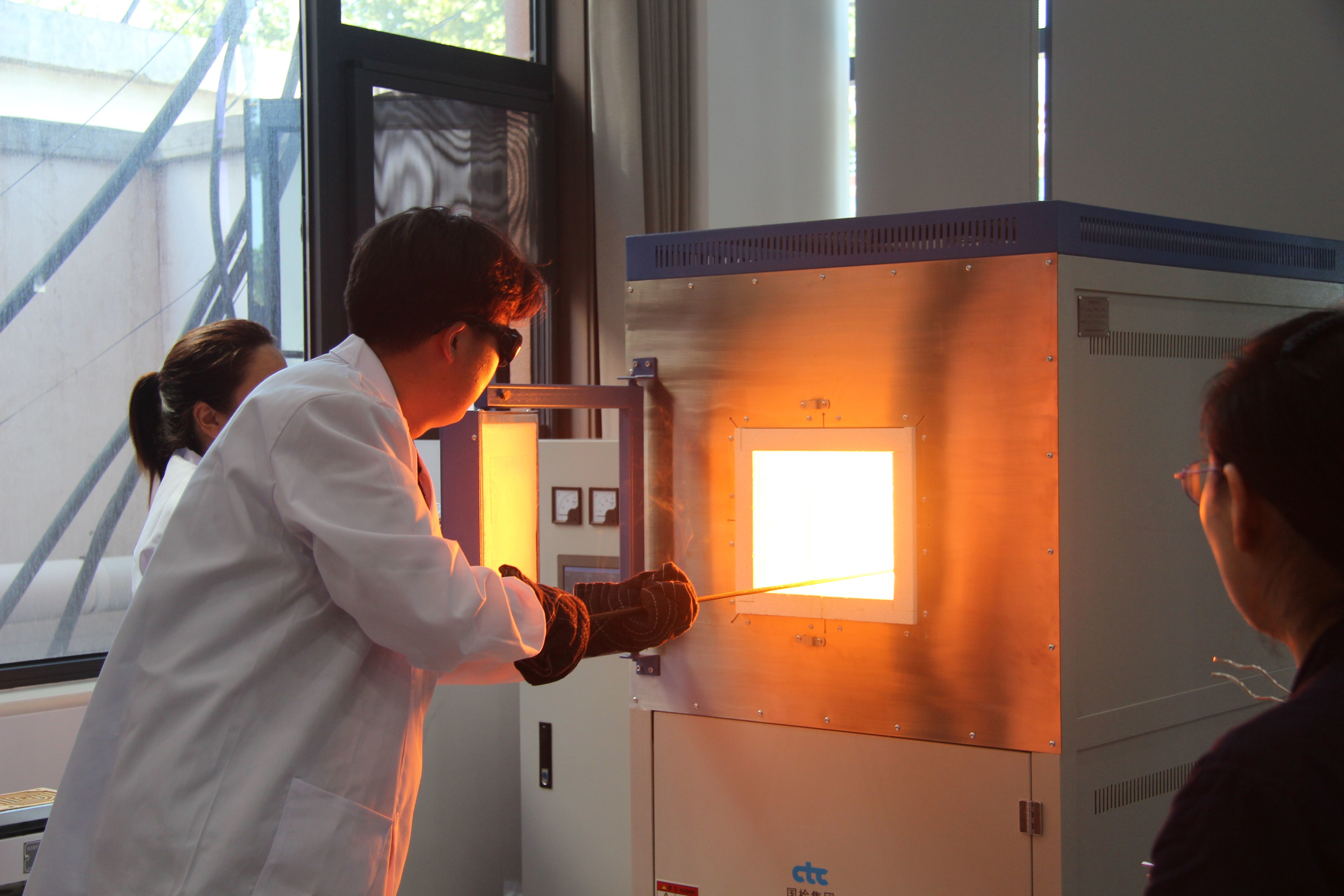

33. Static Corrosion Resistance Testing: Sample each batch of products, soak the electric melting brick samples in1500℃ constant temperature glass liquid,36and measure the corrosion situation after hours with precision instruments to accurately determine whether their performance indicators are qualified.

Recommended content

Share to