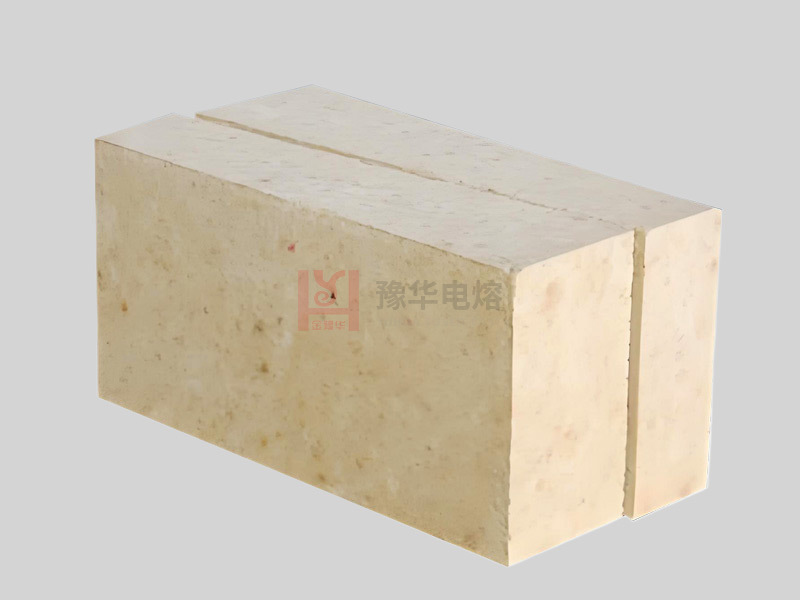

china High alumina brick

Time:

Apr 16,2025

High alumina brick is a refractory material. It is mainly composed of alumina, which gives it excellent heat - resistant properties. With high strength and good resistance to abrasion and chemical corrosion, it is widely used in furnaces, kilns in industries like metallurgy, ceramics, and glassmaking.

Production method:

High alumina brick is a kind of refractory material, the main component of this refractory brick is Al2O3. In our country, according to the content of Al2O3 in high alumina bricks, it is usually divided into Three classes: the content of Al2O3 in the first grade high alumina brick is> 75%; the content of Al2O3 in the second grade high alumina brick is 60 ~ 75%; the content of Al2O3 in the third grade high alumina brick is 48 ~ 60%.

Product details: high alumina brick is a kind of refractory material, the main component of this refractory brick is Al2O3. In China, according to the content of Al2O3 in high alumina bricks, it is usually Divided into three classes: the content of Al2O3 in the first grade high alumina brick is> 75%; the content of Al2O3 in the second grade high alumina brick is 60 ~ 75%; the content of Al2O3 in the third grade high alumina brick is 48 ~ 60%. High alumina brick alumina content in more than 48% of a neutral refractory. It is formed by forming and calcining raw materials with high alumina content. High thermal stability, refractoriness above 1770 ℃.

Product Features:

1. Refractory: The fire resistance of high alumina bricks is higher than that of clay bricks and semi-silica bricks, reaching 1750~1790 ℃.

2. Load softening temperature: because of high aluminum products in Al2O3 high, less impurities, the formation of fusible glass body less, so the load softening temperature is higher than clay bricks, but because the Molai stone crystallization did not form a mesh organization, so the load softening temperature is still not high silicon brick.

3. Slag resistance: Al2O3 is more in high alumina bricks, which is close to neutral refractory materials and can resist the erosion of acidic slag and alkaline slag. Because it contains SiO2, the ability to resist alkaline slag is weaker than that of acidic slag.

4. Product use: high alumina brick is mainly used for masonry blast furnace, hot blast stove, electric furnace top, blast furnace, reverberatory furnace, rotary kiln lining. In addition, high alumina bricks are also widely used as open-hearth regenerative lattice bricks, plug heads for gating systems, and water mouth bricks. However, the price of high alumina bricks is higher than that of clay bricks, so it is not necessary to use high alumina bricks where clay bricks can meet the requirements.

Physical and chemical indicators:

Physical And chemical Indexes Of high Alumina Brick | ||||

Name | Super High Alumina Brick | Grade I High Alumina Brick | Grade II High Alumina Brick | Grade III High Alumina Brick |

Brand | LZ-80 | LZ-75 | LZ-65 | LZ-55 |

AI203% ≥ | 85 | 75 | 65 | 55 |

Fe203%< | 2 | 2.5 | 2.5 | 2.6 |

Bulk Density g/cm2 | 2.6 | 2.5 | 2.4 | 2.3 |

Normal Temperature Compressive Strength Mpa> | 80 | 70 | 60 | 50 |

Load Softening Degree ℃ | 1550 | 1510 | 1460 | 1420 |

Refractoriness ℃ | 1790 | 1790 | 1770 | 1770 |

Apceptive Porosity% < | 21 | 22 | 23 | 24 |

Rate Of Change Of Line% | -0.2 | -0.3 | -0.4 | -0.4 |

Recommended content

Share to