YUHUA FUSED CAST

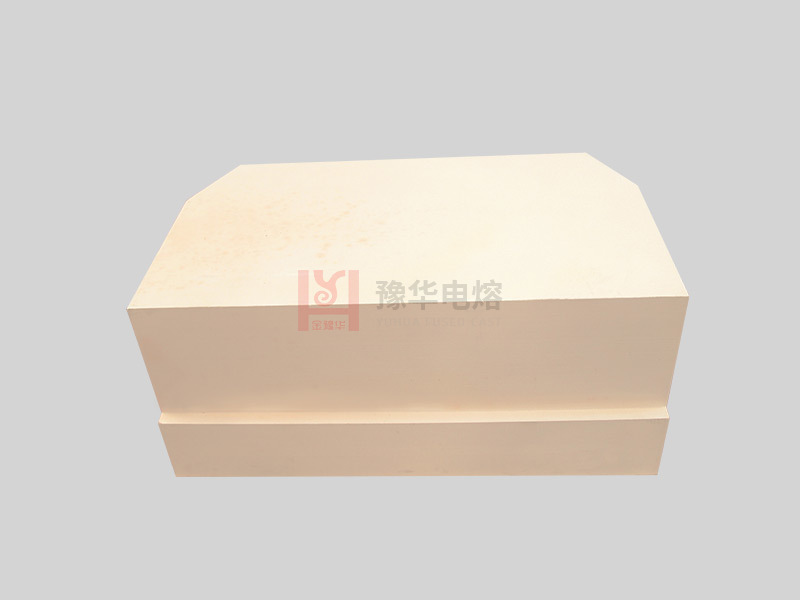

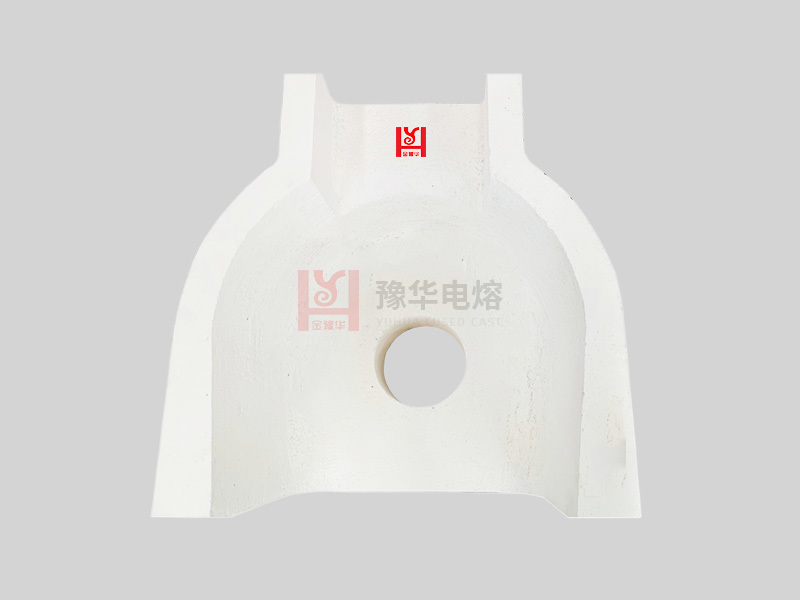

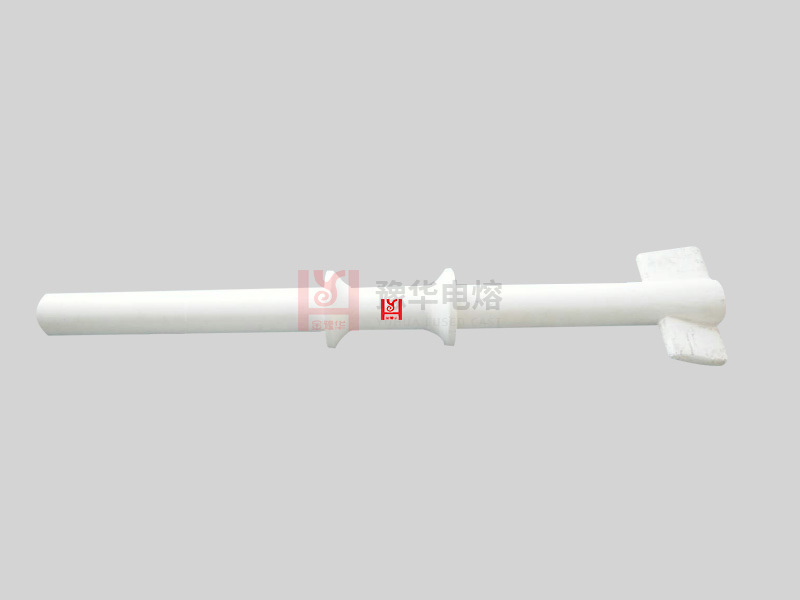

Hot Products

Category

YUHUA FUSED CAST

APPLICATION

If you want more product information

Leave your contact information and get a free product quote

WHY CHOOSE US

20+

Yuhua Fused Cast has been in the business of fused zirconia corundum refractories for glass kilns for more than 20 years, providing customized solutions for every glass kiln application.

30+

Yuhua Fused Cast Believing in innovation and development is the fundamental principle. We have over 30 independently developed patented technologies to meet the various needs of glass manufacturers.

60+

With a technical service team of 68 people to assist customers in solving problems in 3D design, material selection, construction, operation and maintenance.

20000+

Has three fused corundum production lines with an annual production capacity of more than 20,000 tons, and participated in the drafting of "General Design Specification for Glass Melting Kilns" and "Test Method for Resistant to Glass Liquid Erosion under Dynamic for Refractories Used in Glass Melting Kilns".

48000+

Our headquarter has two production bases with a building area of more than 48,000 square meters and advanced inspection and testing equipment in China.

Source manufacturers

Source manufacturers - directly from the manufacturer to obtain the first-hand source, affordable, reliable quality, with peace of mind!

High tech testing equipment

Ensures worry free quality

YUHUA FUSED CAST

ABOUT YUHUA

Henan Yuhua Fused Cast Refractory Co., Ltd, established in 2002, is a high-tech enterprise that dedicated to the production and sales of fused cast zirconium corundum series. The company is located in Chaohua Industrial Park, Xinmi City, Henan Province, covering the area of more than 48,000 square meters. Now has fixed assets of 260 million yuan, two production bases, three automatic production lines, annual output of more than 20,000 tons......

YUHUA FUSED CAST

Case Show

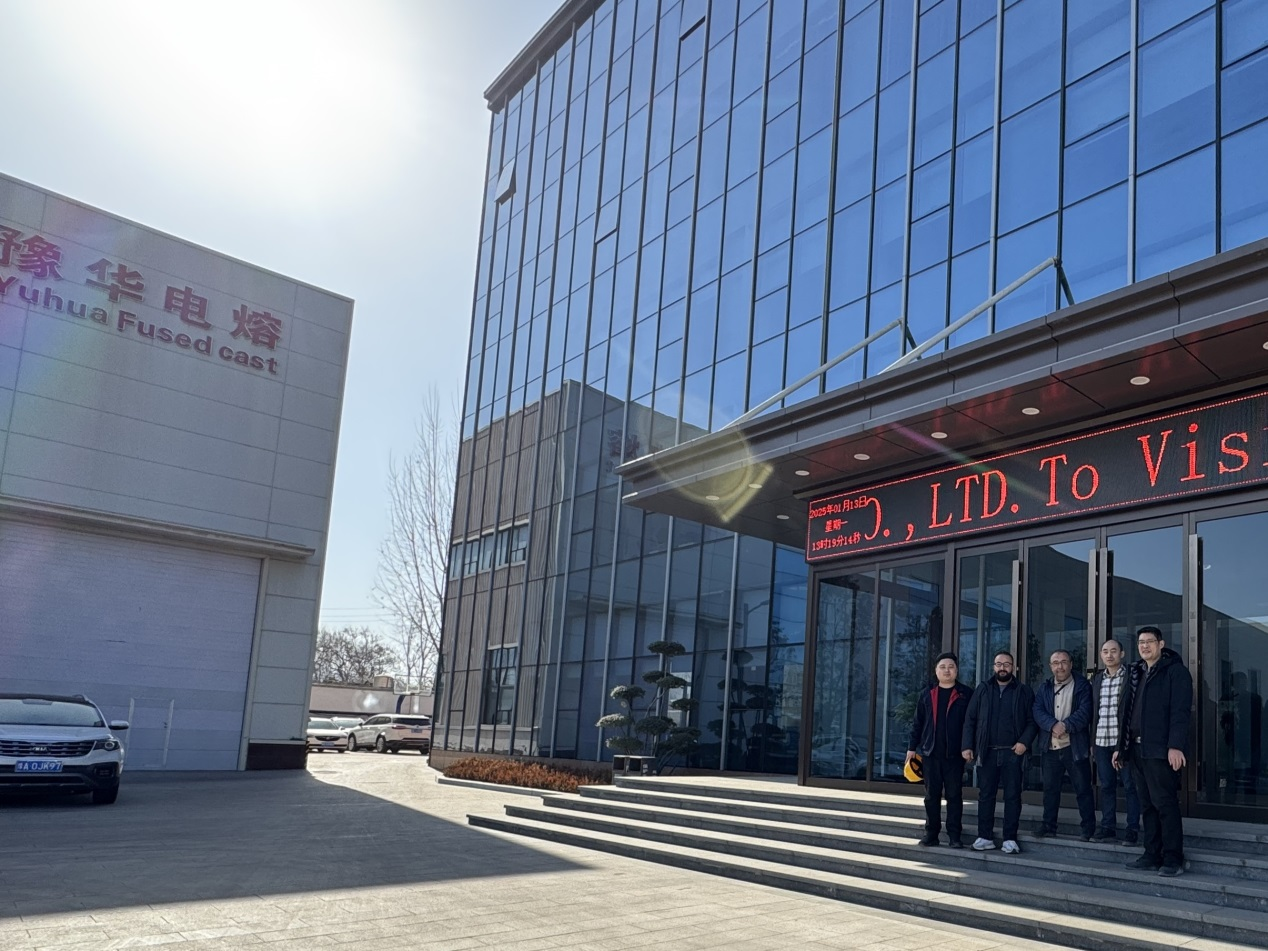

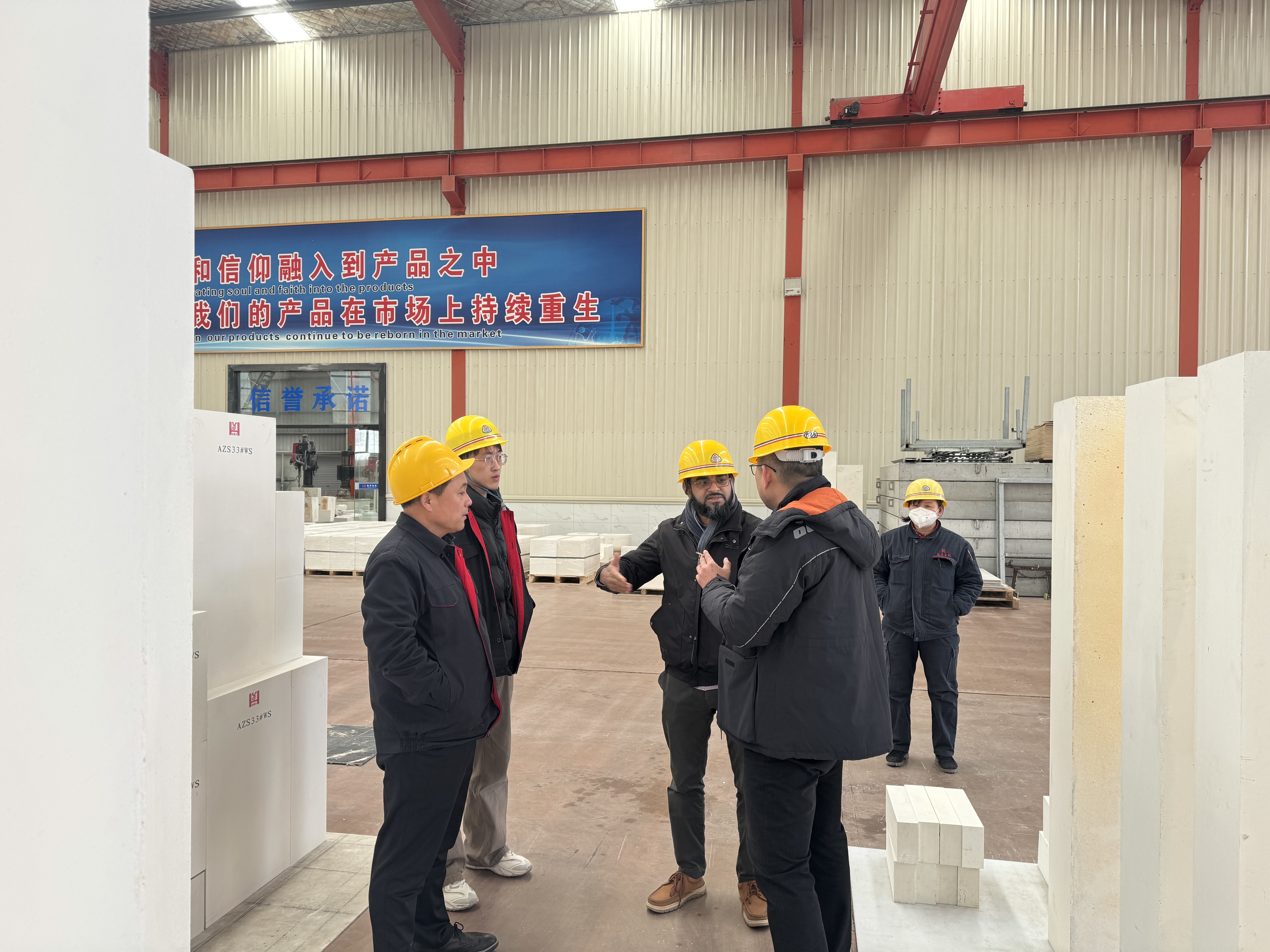

Belarusian clients visited Yuhua for an inspection

On January 16, 2025, at 10:30 AM, the Belarusian client arrived at the company for an inspection.

Read MoreAlgerian customers come to Yuhua Fused Cast that process the inspect

At 9:30 am on January 14, 2025, the Algerian customer (ALVER SPA) and the technical department of Chongqing JEFFER ENGINEERING AND TECHNOLOGY CO., LTD. came to Henan Yuhua Fused Cast Refractory Co., LTD., to accept the overall assembly of 80㎡ oxygen burning glass kiln.

Read MoreLibya customer visit our company

Dr. Liu from Chongqing Jeffer Furnace Company, a strategic partner of Yuhua Fused Cast, visited our company with clients from Libya.

Read More

YUHUA FUSED CAST

BLOG UPDATE